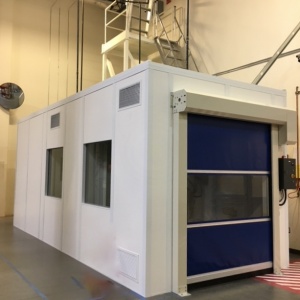

Modular Cleanroom Construction

Class One Cleanrooms has been a leader in modular cleanroom construction since 1979. Modular cleanroom construction makes for a flexible and cost-effective clean room build. Class One Cleanrooms modular wall system is a non-progressive demountable modular cleanroom construction that offers flexibility for future clean room expansion and/or modification.

We have a reputation for building the most challenging cleanroom projects and can build your modular cleanroom project whether you have a small or large cleanroom project you will find we will have the best approach.

Our superior modular walls are prefabricated and factory engineered to accommodate your cleanroom requirements. Prefabricated modular cleanroom walls can be designed as a totally freestanding self-contained room or integrated with your existing walls.

Aluminum honeycomb panels are the most popular modular cleanroom panels used in electronics clean room construction because they are non-out-gassing, non-particle shedding, anti-static, and non-combustible. Modular wall panels made of FRP (reinforced plastic) and HPL (high-pressure laminate) are used most often in the pharmaceutical, USP 797-800 compounding rooms, and medical device clean rooms. These panels can withstand repeated cleaning and sanitize without breaking down.

View Gallery of Cleanroom Projects

Since we are also the clean room manufacturer Class One Cleanroom Systems has a greater control of project quality, scheduling, and costs. With our own cleanroom factory located in California, we can provide you with factory direct prices and modular cleanroom products along with our design and engineering to give you the best modular cleanroom in the industry. Another cost savings to consider when choosing modular construction is that modular cleanrooms are considered equipment, not a part of the existing building. Modular cleanrooms may have a tax advantage because they can be depreciated at an accelerated rate ask your CPA.