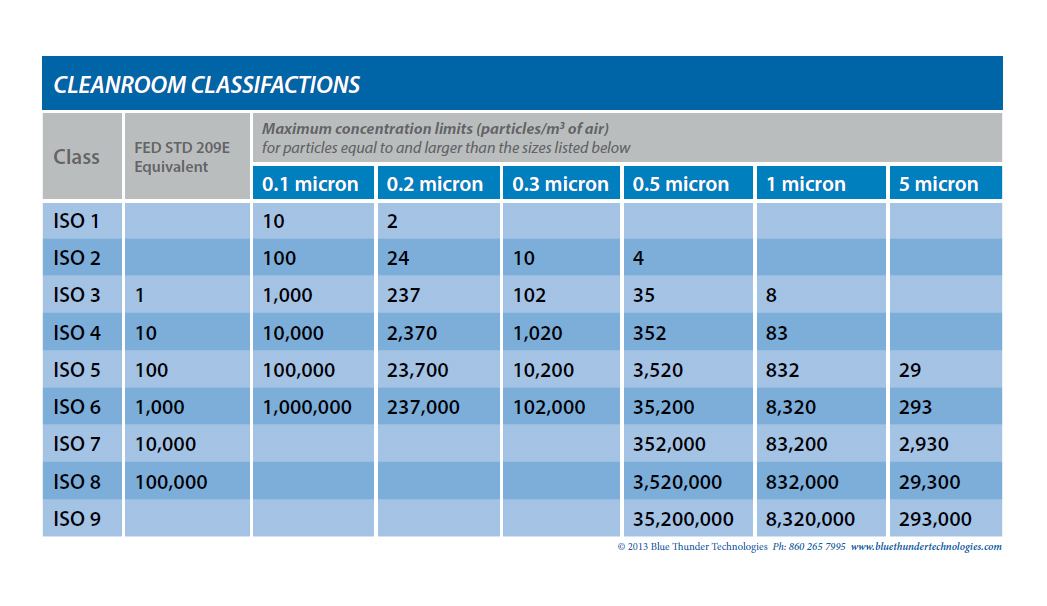

Cleanrooms have standardized class ratings that indicate the number of particles for each square meter or sq. ft. of air. An ISO Class 3 cleanroom is one of the cleanest human-occupied environments required for today’s technology. The pictured chart identifies the allowable particles sizes and the number of particles per each classification.

While high levels are possible, they are generally not required. Hypothetically cannabis cleanrooms could range from an ISO Class 5 as used in pharmaceutical cleanrooms, or upwards to an ISO Class 8 common for packaging and processing operations. Once the room is completed, most GPS call for testing and certification. We can test and certify your cleanroom to ISO Standards. It is also advised for the owner to purchase a cleanroom particle counter in order to determine the daily status of the room.