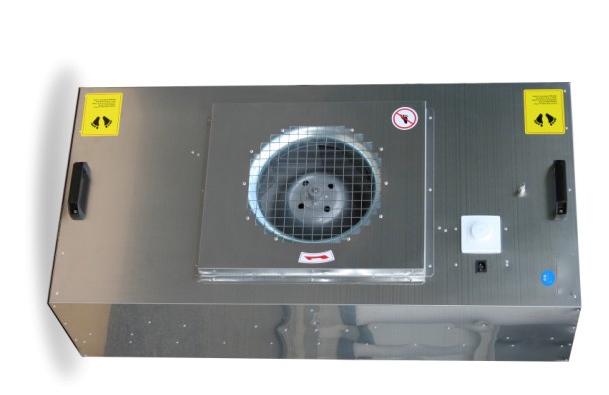

CleanSeal 800 2’ x 4’ HEPA Fan Filter Unit Price $848.00-Each Low Energy-Low Noise-Low cost Special Price UL listed ETL listed. (Room-Side Replaceable Option Available)

Class One Cleanrooms HEPA Fan filter units consist of a backward incline fan motor assembly and high-efficiency HEPA/ULPA filter are combined in one unit. The fan filter units are designed to furnish Hepa filtered airflow over the cleanroom area. Our fan filter units (FFU) are used in all applications and classes of cleanroom environments, semiconductor medical manufacturing facilities, as well as pharmaceutical labs. Cleanseal fan filter units are designed for use in Class 10 through Class 100,000 cleanroom spaces.

Class One Cleanrooms has perfected the Hepa Fan Filter Unit (FFU). Over 20 years of manufacturing UL-listed fan filter units we have developed this low noise, low energy low-cost fan filter unit for sale worldwide. This filter along with our CleanSeal cleanroom T-bar ceiling grid, our LED cleanroom lights fixtures reduce the overall energy of your cleanroom also saving air conditioning costs through lower heat loads. Class One Cleanrooms gasket heavy-duty clean room ceiling system is the perfect fit with our LED cleanroom 50-watt flat panel cleanroom light.

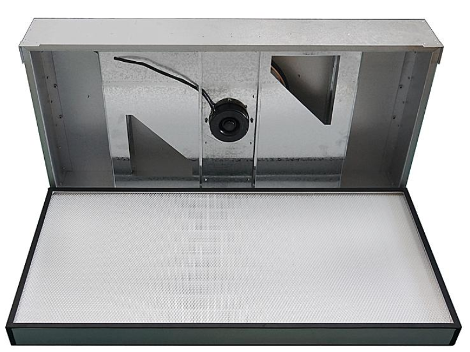

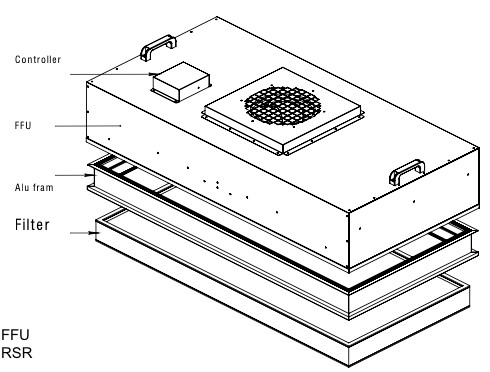

A fan filter unit (FFU) is a type of air filtering equipment. It is used to supply purified air to cleanrooms or microenvironments by filtering out harmful airborne particles from the recirculating air. The units are installed within the system’s ceiling or floor grid. Large cleanrooms require a proportionally large number of FFUs, which in some cases may range from several hundred to several thousand. Units often contain their own pre-filter, HEPA filter, and internally controllable fan air distribution.

FFUs can be used in place of a more conventional recirculating air unit such as a ducted or plenum design. FFUs are often used because of height restrictions in the space; they are the only systems that work in setups with smaller internal floor dimensions. Fan powered HEPA, FFU design is generally considered to be less expensive than a more conventional ducted supply system.

HEPA Fan filter unit

Fan filter unit Plenum Design

The Hepa Fan Filter Unit (FFU) motorized Hepa filters offers many advantages for cleanroom construction. Paul Varni, President of Class One Cleanrooms, takes a look at its popular use in new and cleanroom conversions; new low-energy FFUs give an exciting future ahead. Since their initial introduction in 1984, fan filter units (FFUs) have proved a popular choice for cleanrooms and continue to be so today. Initially used in ISO Class 5 cleanrooms and above, with a negative plenum design, FFU sales soon grew and matured into a world market and saw a range of manufacturers and brands emerging in this area. Our new low energy FFU fan filter units to meet new ISO cleanroom requirements using less energy and heat load. The technology is very simple – Fan filter Units are more than a HEPA or ULPA filter attached to a ‘plug’ fan. Fan filter units are installed within a standard cleanroom gasket 2″ ceiling grid to offer HEPA filtration for the cleanroom space. The simplicity of operation and installation is exciting; so too are the significant additional benefits the FFU provides. Clearly, fan filter units Offer a low initial cost, low noise easy to service with the need for balancing as with ducted Hepa filters. But there are many other advantages also. Most notability, incorporating FFUs within negative plenum designs allows much smaller air handling units to be specified for a particular cleanroom installation, saving space needed for the ducting cost and energy. In this cleanroom plenum design, the plenum becomes a mixing box for the conditioned air and allows future cleanroom upgrades to a higher class with the need to add more ducting. Clean room ceiling systems developed by UL approved fan filter units that only use 120 watts each. Along with our gasket cleanroom ceiling grid system and LED cleanroom lighting make-up for the most energy efficient cleanroom design today.

The lower energy needed using the fan filter unit design allows much lower heat generated by the Hepa fan filter units 120v at 170 watts each along with cleanroom rated led lighting will reduce the size of the air handler size and further reduce the energy need for the cleanroom. Ducted Hepa filters are used when the requirement for tight temperature control in needed less the +/- 1 degree.

Cleanseal 800 EC Motor 2’ x 4’ Fan Filter Unit- Low Energy-Low Noise-low cost

Fan filter units consist of a backward incline EC fan motor assembly and high-efficiency HEPA or ULPA filter are combined in one unit. The fan filter units are designed to furnish Hepa filtered airflow over the cleanroom area. Our fan filter units (FFU) are used in all applications and classes of cleanroom environments, semiconductor medical manufacturing facilities, as well as pharmaceutical labs. Cleanseal fan filter units are designed for use in Class 10 through Class 100,000 cleanroom spaces. Conforms to UL STD 507. Certified to CSA STD.C22.2 No.113.

Class One Cleanrooms has perfected the Hepa Fan Filter Unit (FFU). Over 20 years of manufacturing UL listed fan filter units we have developed this low noise, low energy low cost fan filter unit for sale worldwide. This filter along with our Cleanseal cleanroom T-bar ceiling grid is a must have for all your cleanroom needs.

Optional Room Side Replaceable filter (Size 47-5/8” L x 23-5/8” W x 14-3/8” D)

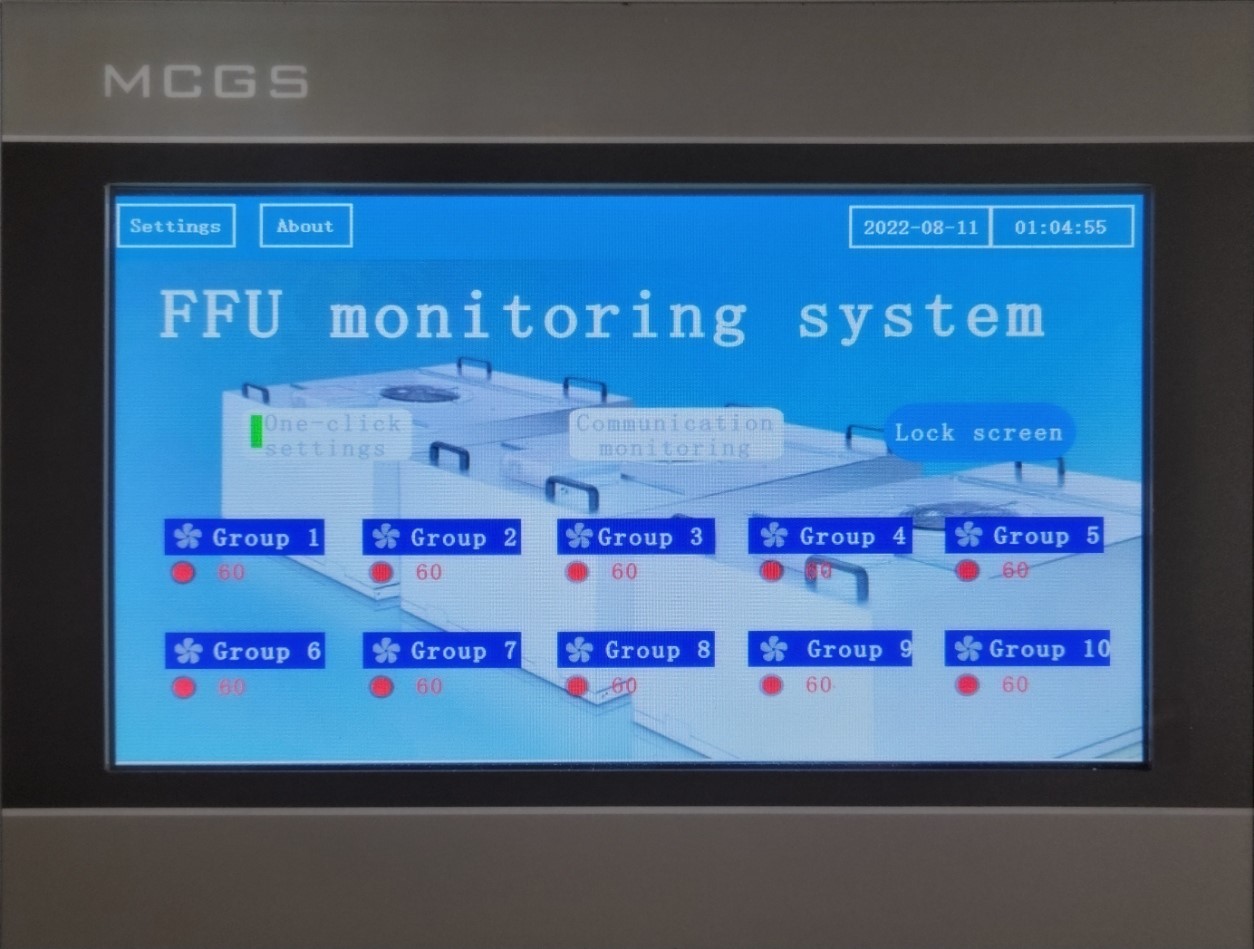

Optional Control System (Up to 600 FFU’s)

Optional Control System (Up to 600 FFU’s)

HEPA Fan Filter Unit Specifications |

|

|

Size |

47-5/8” L x 23-5/8” W x 13-3/8″ D |

| CFM Maximum | 785 |

| Main Body (standard) | Galvalume |

| HEPA Filter | 99.995% (Optional ULPA Filter 99.9995%) |

| Power Supply | 208‐240v ac 50-60 Hz (120v Optional) |

| Power Consumption | 170 Watt .6 Amps |

| Sound | 46-‐52 db |

| Weight | 65 lbs. |

| Options | Remote Control, Pre‐Filter. Differential Gauge, Control System, 110v Transformer. |